Work Bench

Monitor daily performance of your inventory, service levels and adherence to the plan with clear defined quick drill through planner specific KPI’s.

Online Demo

Want your old paradigms to change? Your journey has to begin with training, not just for an individual, but for the mindset of the entire team.

Training

To ensure a successful deployment, you need organisational buy-in and confidence. Your pilot and simulations are designed to do just that.

Training

With the right thought ware and organisational buy-in due to the results of the pilot, you are ready to start the journey.

Training

As you world changes, your organisation needs to change with it. B2Wise business leaders will be there to help you achieve your goals.

Training

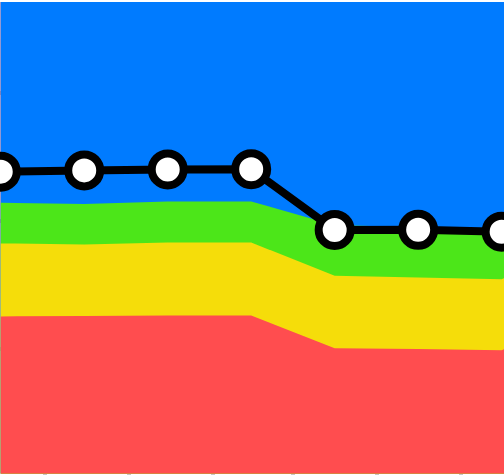

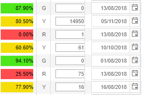

Monitor daily performance of your inventory, service levels and adherence to the plan with clear defined quick drill through planner specific KPI’s.

Online Demo

Determine your strategic buffer positions, automatically calculate the decoupling lead times and required inventory levels.

Online Demo

Use individual part or group policy settings to model and set buffer levels at your decoupling points.

Online Demo

Apply forecasts or planned adjustment factors to automatically adjust buffers for seasonal, shutdown, end of life and superseded parts.

Online Demo

Sense changing customer demand in order to generate the required purchase, works and distributed orders - all in real time.

Online Demo

Alert planners as to which purchase, works and distributed orders need to be executed in order to protect availability and enhance the flow

Online DemoSince its inspection in the 1950, the majority of companies have implemented a forecast driven MRP and DRP planning and execution model that now comes as standard with most ERP systems. However we now live in a VUCA (Volatile, Uncertain, Complex, Ambiguous) world and this de facto planning solution that was conceived over 60 years ago is not delivering the goods anymore. Companies constantly oscillate from having too much inventory aimed at protecting customer service to having to little inventories, and thus poor service levels, driven by the need to save money.

By combining MRP and DRP with the flow based methodologies of lean, theory of constraints and six sigma,

a new more relevant approach for today’s VUCA world has been developed called demand driven MRP or DDMRP

for short. Companies that have adopted DDMRP have seen service rate of close to 100% while at the same

time reductions of inventory of between 15 to 65%.

DDMRP is fast becoming the new engine of supply

chain planning and execution. In order to maximise the performance of this new supply chain planning and

execution engine a new operating model has been developed called Demand Driven Sales & Operations

Planning or DDS&OP. DDS&OP controls the parameters of DDMRP and allow the organisations to transform from

a cost-centric enterprise to a flow-focused enterprise.

At B2Wise we have embraced these new

methodologies and are dedicated to building new technologies and implementation methodologies to support

both DDMRP and DDS&OP.